Belmore Colored Contacts Brand

Belmore Colored Contacts Brand

Innovative Leader in Colored Contacts Technology

Belmore has established itself as a pioneer in the contact lenses industry, particularly in the colored contacts segment. Since its inception, Belmore has been at the forefront of technological advancements and innovation in contact lenses manufacturing.

Major Milestones in Belmore's History

- 2012: Launched 'Daily Fit' (Clear 53, Color 53), a daily disposable contact lenses.

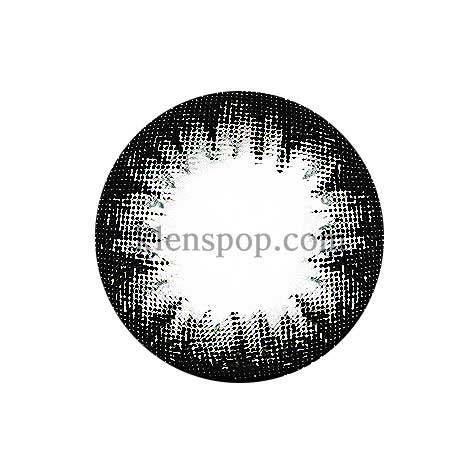

- 2008: Introduced 2nd generation colored contacts and 'Bonne Natural Fit,' a color silicone hydrogel lenses. Released RGP lens BMG (soft RGP lens) and budget-friendly silicone hydrogel lenses 'Cio (Clear & Color).'

- 2007: First in Asia to develop an unmanned automated separation system.

- 2011: Launched silicone hydrogel lenses 'Bonne Adfit.' Developed vision checkers and released silicone RCP lens 'Flexiart.' Expanded soft contact lenses production line.

- 2006: Selected as a clean factory by Korea Daily News and Korea Occupational Safety. Applied for FDA and Japanese Ministry of Health, Labour and Welfare certifications. Selected as a clean factory by Korea Ministry of Labor. Expanded precision optical processing equipment Cplotorm80.

- 2010: Relocated the main factory.

- 2005: Launched 45% and 55% soft contact lenses. Changed corporate name to Belmore Contact Co., Ltd. Released 38% astigmatism soft contact lenses. Acquired various certifications and venture business certification.

- 2002: Released 38% soft contact lenses. Established a corporate research institute. Released RGP lenses BM3, BM7. Acquired aspheric production patent and KGMP certification.

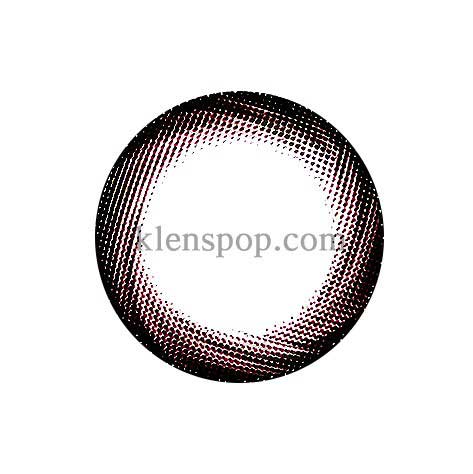

- 2009: Launched 3-tone colored contacts. Established Belmore Co., Ltd. Developed 45%, 65% colored contacts. Released RGP lens BM9 (UV protection, DK100).

Advanced Manufacturing and Quality Assurance

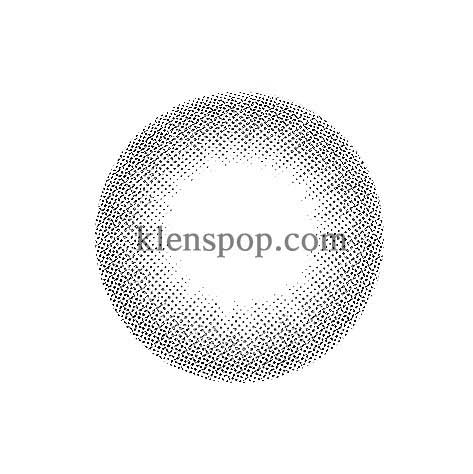

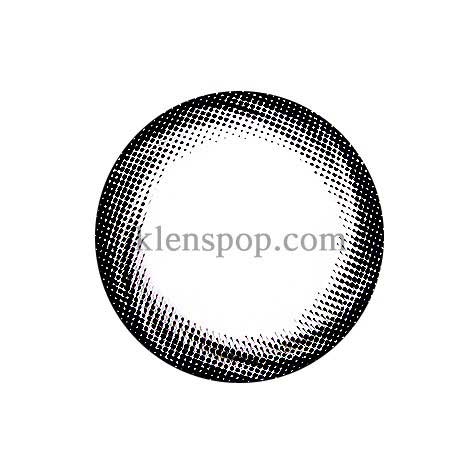

Belmore's products are manufactured in a 10,000 CLASS clean room, compliant with ISO 14644, ensuring safety from contaminants like dust and microbes. The company employs an unmanned automated casting mold system for all products, enhancing the production quality. This high-resolution aspheric design technology ensures distortion-free and clear vision.

Particularly noteworthy is Belmore's achievement in developing Asia's first unmanned automated colored contacts line. Their colored contacts products combine their unique Casting Mold System with C.I.P technology, ensuring safe, comfortable, and lightweight contact lenses. Every product undergoes thorough inspections before distribution.

Commitment to Excellence

Belmore's C.I.P method - Color Monomer Inter Polymerization process - is a cutting-edge technique where color gets embedded between lens particles during polymerization, enhancing both safety and comfort. Belmore remains committed to supplying high-quality, safe products, continually advancing in colored contacts technology.

In essence, Belmore stands as a symbol of innovation and quality in the colored contacts market, consistently pushing the boundaries of technology and safety in eye care.